Superior Chemical Properties

SuperiorTensile Strength

Superior UTS/YS ratio

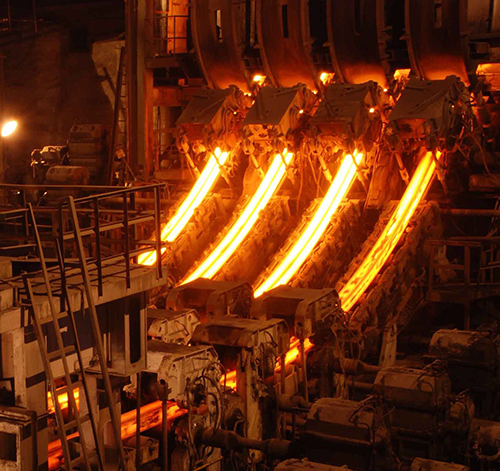

Nirman TMT (thermos-mechanically-treated) rebars (reinforcing bar) are used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Our high quality physical and mechanical specifications help to significantly increase the tensile strength of the structure. Our hot rolled round bars with deformation at its surface promotes a strong bond with the concrete. Nirman TMT is manufactured using our integrated manufacturing process starting from ironmaking. High grade iron ore and pellets are processed into high quality sponge iron in our facilities which is then converted into crude steel in our steel melting shop. 500D is our flagship offering in the pool of available options and sizes. We are able to provide best-quality tmt rebars by controlling all the parameters in the manufacturing process, lab testing, and by implementing quality control mechanisms. Less steel is required during construction due to the high quality of the product which provides cost-saving, hence making Nirman TMT an economically priced product.

| Q U A L I T Y C O M P A R I S O N M A T R I X | |||

| TECHNICAL PARAMETERS | ISI GRADE | OTHER PLAYERS | NIRMAAN TMT |

| Mechanical Properties | Fe - 500D | Fe - 500D | NIRMAAN Fe -500D |

| Proof Stress (Min) | 500 N/MM2 | 530 N/MM2 | 550 N/MM2 |

| Tensile Strength (Min) | 565 N/MM2 | 600 N/MM2 | 650 N/MM2 |

| TS/YS Ratio(Min) | 1.10 | 1.10 | 1.12 |

| Elongation | 16% | 18% | 18% |

| Bend Test (Min) | Up to 20 mm - 3D Above 20 mm - 4D | Up to 20 mm - 3D Above 20 mm - 4D | Up to 20 mm - 3D Above 20 mm - 4D |

| CHEMICAL COMPOSITION (%) | |||

| Carbon | 0.250% | 0.250% | 0.240% |

| Sulphur | 0.040% | 0.040% | 0.035% |

| Phosphorus | 0.040% | 0.040% | 0.035% |

| S + P | 0.075% | 0.075% | 0.070% |

| TECHNICAL PARAMETERS | ISI GRADE | OTHER PLAYERS | NIRMAAN TMT |

| Mechanical Properties | Fe - 550D | Fe - 550D | NIRMAAN Fe -550D |

| Proof Stress (Min) | 550 N/MM2 | 550 N/MM2 | 590 N/MM2 |

| Tensile Strength (Min) | 585 N/MM2 | 600 N/MM2 | 650 N/MM2 |

| TS/YS Ratio(Min) | 1.25 | 1.25 | 1.25 |

| Elongation | 10% | 15% | 16% |

| Bend Test (Min) | Up to 20 mm - 5D Above 20 mm - 6D | Up to 20 mm - 5D Above 20 mm - 6D | Up to 20 mm - 5D Above 20 mm - 6D |

| CHEMICAL COMPOSITION (%) | |||

| Carbon | 0.30 MAX | 0.28 MAX | 0.23 MAX |

| Sulphur | 0.055 MAX | 0.055 MAX | 0.050 MAX |

| Phosphorus | 0.055 MAX | 0.055 MAX | 0.050 MAX |

| S + P | 0.100 MAX | 0.090 MAX | 0.090 MAX |

| TECHNICAL PARAMETERS | ISI GRADE | OTHER PLAYERS | NIRMAAN TMT |

| Mechanical Properties | Fe - 500D | Fe - 500D | NIRMAAN Fe -500D |

| Proof Stress (Min) | 500 N/MM2 | 510 N/MM2 | 530 N/MM2 |

| Tensile Strength (Min) | 545 N/MM2 | 580 N/MM2 | 600 N/MM2 |

| TS/YS Ratio(Min) | 1.08 | 1.10 | 1.10 |

| Elongation | 12% | 14% | 16% |

| Bend Test (Min) | Up to 20 mm - 4D Above 20 mm - 5D | Up to 20 mm - 4D Above 20 mm - 5D | Up to 20 mm - 4D Above 20 mm - 5D |

| CHEMICAL COMPOSITION (%) | |||

| Carbon | 0.30 MAX | 0.28 MAX | 0.23 MAX |

| Sulphur | 0.055 MAX | 0.055 MAX | 0.050 MAX |

| Phosphorus | 0.055 MAX | 0.055 MAX | 0.050 MAX |

| S + P | 0.105 MAX | 0.105 MAX | 0.095 MAX |

| Mn | 0.50 MIN | 0.50 MIN | 0.50 MIN |

| P R O D U C T & S I Z E R A N G E (Bundle Length 12 Mtrs) | |||

| GRADES AVAILABLE IN Fe 500 , Fe 500D & Fe 550 | |||

| STRAIGHT & BEND (In mm) | |||

| 5.5, 6 , 7 , 8 , 10 , 12, 16 , 20, 25, 28, 32 & 36 | |||